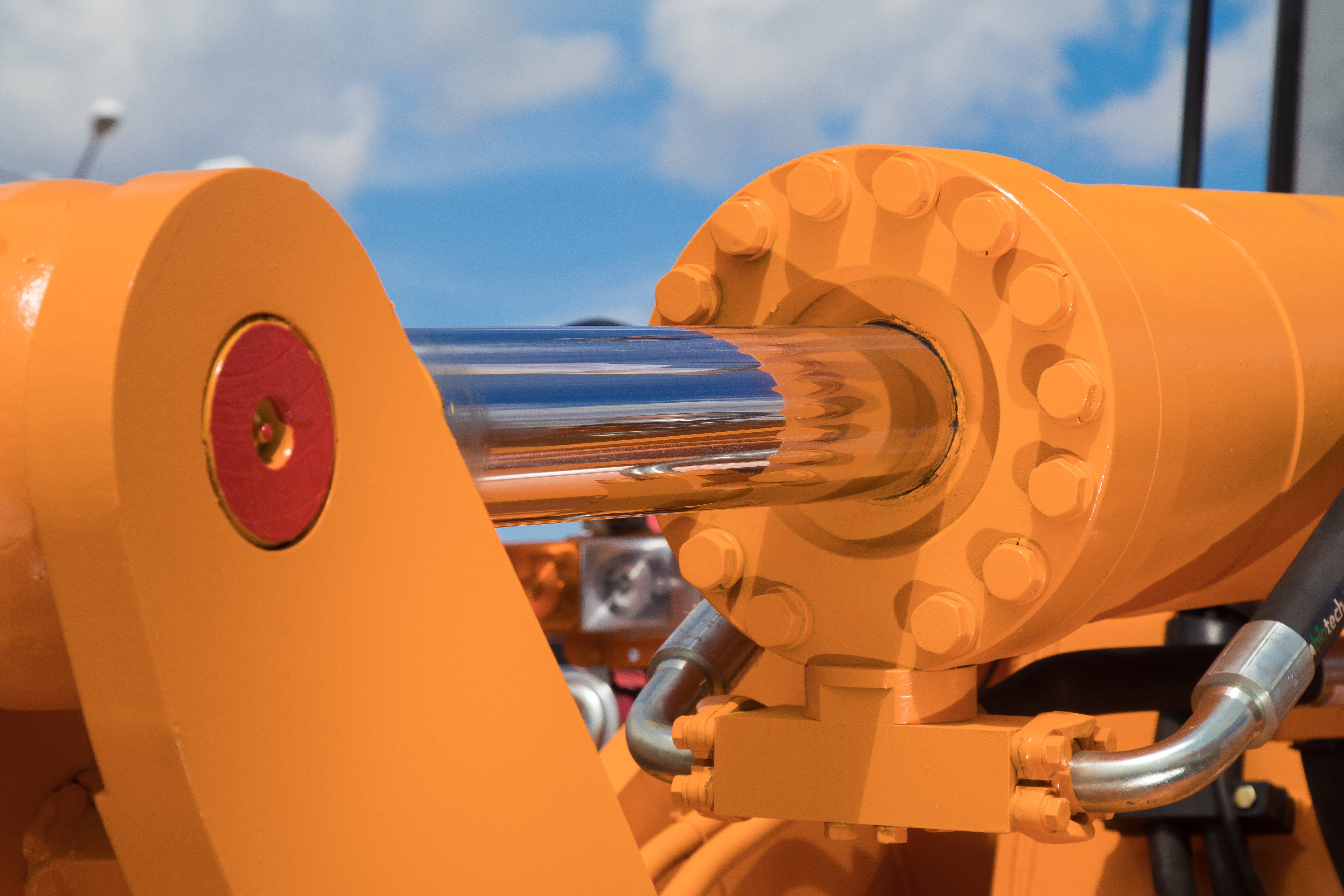

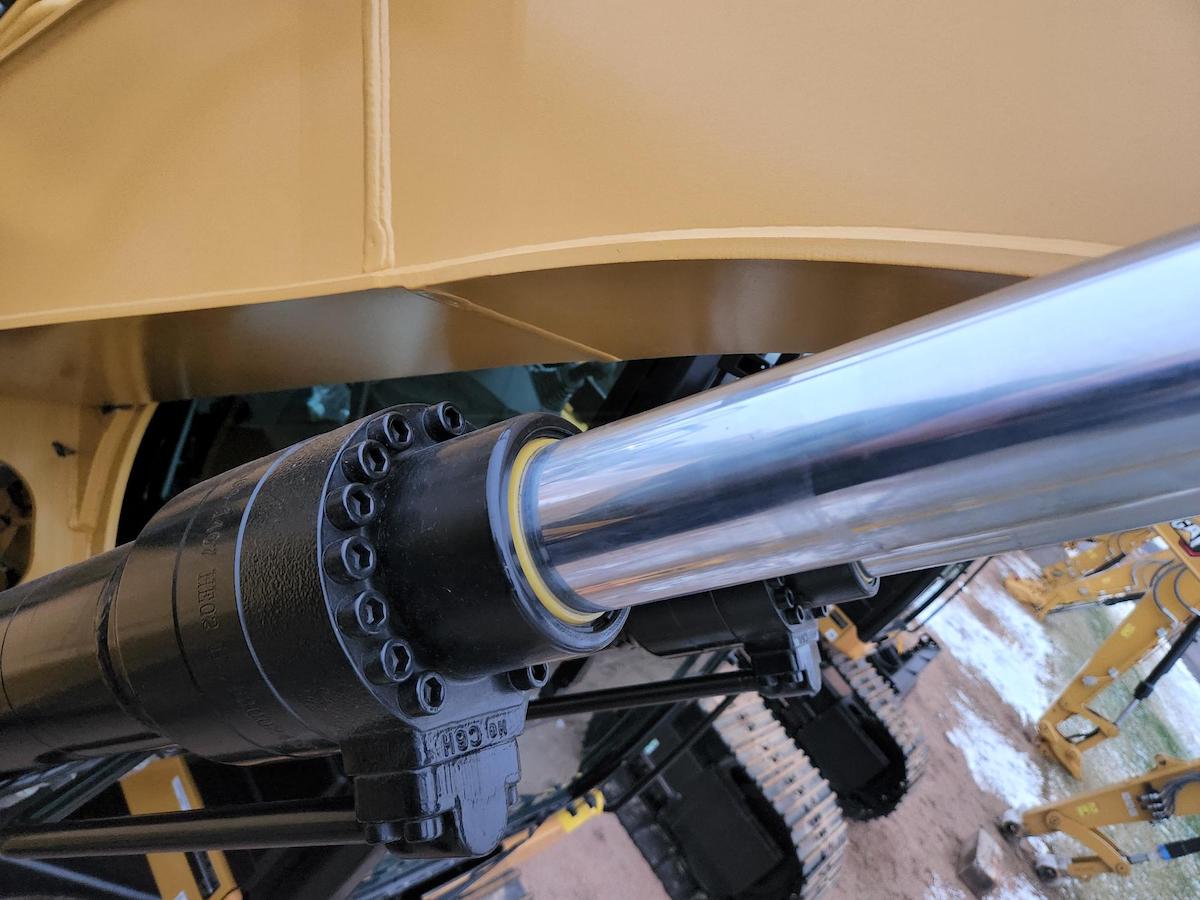

Maximize Hydraulic Cylinder Performance with Strong Field Support

When it comes to hydraulic cylinders used in applications ranging from Aerospace & Defense to Transportation to Mining & Construction to Industrial Handling, having strong field support from engineers and technicians allows you to eliminate hidden costs. To be clear, we define those charges as ones exceeding the product’s purchase price and routine maintenance, and which can add up quickly.

If you source your cylinders from overseas, it is impossible to get the necessary support when problems arise. As a result, your company pays the price because, to paraphrase a popular saying, downtime is money, and that attractive purchase price often comes with steep hidden costs.

If you source your cylinders from overseas, it is impossible to get the necessary support when problems arise. As a result, your company pays the price because, to paraphrase a popular saying, downtime is money, and that attractive purchase price often comes with steep hidden costs.

Below are 20 advantages you can experience by making purchasing decisions based on more than price and instead sourcing your cylinders from a highly responsive partner committed to helping you maximize the operating life of your cylinders:

-

- Less Downtime.

With strong engineering and technical support, diagnosing and fixing issues can occur quickly, leading to reduced amounts of time your equipment is out of service. In our experience, it’s a contrast of hours or days vs. weeks or months. - Improved Productivity.

Accelerated maintenance and repair schedules from a partner who is “close to home” can keep your operations flowing smoothly so you can operate most efficiently. - Lower Repair Costs.

Minor issues can become major problems if not addressed promptly, leading to more expensive repairs. (i.e., hidden costs) - Longer Equipment Lifespan.

Proper maintenance provided or advised by a supply chain partner, and timely interventions as appropriate, can increase operating life. - Lower Labor Costs.

Overtime or additional staffing becomes unnecessary when you address maintenance, operations, and repair issues routinely and proactively instead of reacting to them in a crisis mode. - Reduced Safety Risks.

Strong engineering and technical support can help to create safe working conditions, which lower the risk of workplace accidents and injuries occurring. - Fewer Quality Issues.

Well-maintained equipment that functions optimally improves product quality, resulting in high levels of customer satisfaction (and better customer retention). - More Efficient Use of Resources.

With proper guidance, oil, seals, and other consumables can be used most effectively and in ways that prevent expensive waste such as leakage and disposal costs. - Better Inventory Management.

Engineers and technicians who know your business can help you efficiently manage inventory, so you always stock the ideal quantities of replacement parts and components. - Lower Training Costs.

By relying on the expertise of engineers and technicians, your team members do not need to be trained to diagnose and solve cylinder-related problems and can instead focus on their core responsibilities.

- Few or No Environmental Cleanup Costs.

Well-maintained cylinders rarely produce the type of leaks and spills that damage the environment and require remediation services. - Few or No Regulatory Fines.

Compliance with laws, regulations, and industry standards through proper cylinder maintenance and operation reduces or eliminates the probability of incurring financial penalties for non-compliance. - Improved Customer Loyalty.

Hydraulic cylinders that remain operational without malfunctioning increase customers’ confidence in your products and services. - Ability to Consistently Meet Production Deadlines.

Well-maintained cylinders help to minimize equipment failures and enable you and your customers to meet production goals. That high degree of reliability allows you and them to benefit from business opportunities that malfunctioning equipment could prevent you from pursuing. - Lower Insurance Premiums.

Few or no incidents or accidents due to robust engineering and technical support can reduce your insurance expenses. - Better Record-Keeping.

Maintaining proper documentation of cylinder maintenance and repair makes it easy to track maintenance history and predict future needs. - Lower Opportunity Costs.

Investing your resources in pursuing business opportunities rather than “putting out fires” because of malfunctioning equipment helps you generate revenue to keep your business healthy. - Lower Legal Costs.

Reduce or avoid litigation caused by disputes, accidents, or compliance issues resulting from equipment that did not perform as intended. - Avoiding Reputation Damage.

Strong engineering and technical support can put your company in a favorable position with customers, enhancing your company's brand (style of doing business) and reputation (standing as a partner that provides quality products on time). - Better Customer Retention Rates.

Field support provided by a domestic manufacturer allows your company to keep your customer base intact and obtain new ones who have been “burned” by unreliable support and bad service.

- Less Downtime.

To discuss how to make the hidden costs of hydraulic cylinder procurement, maintenance, repair, and operation a thing of the past...